Rapid Dyeing Machine

-

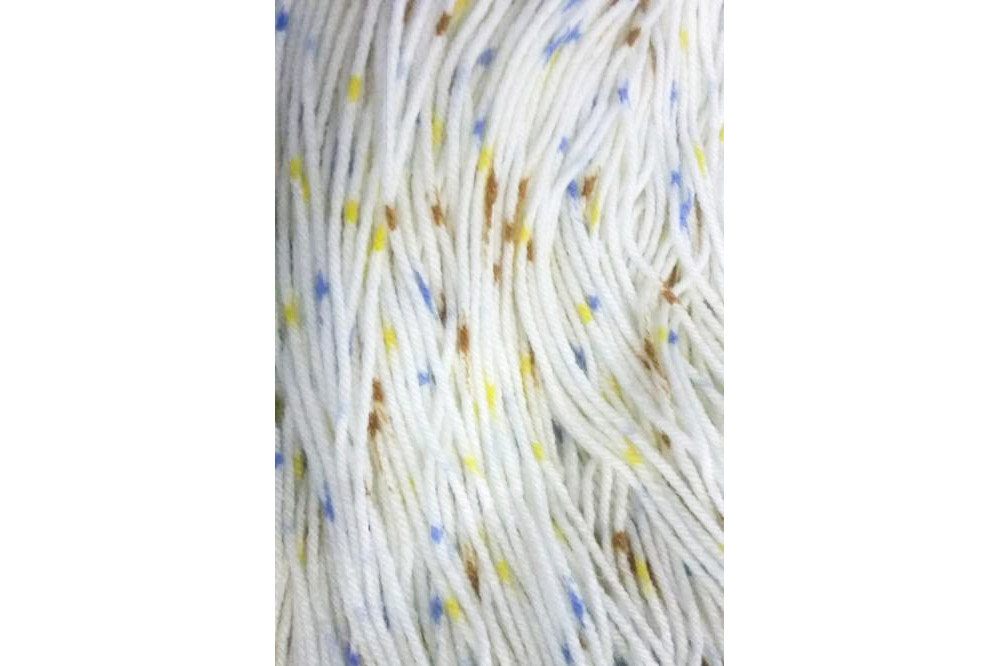

Cedit Rapid Yarn Printing Machine; By separating the yarns in bobbins (cotton, polyester, viscose, acrylic, etc.) movement in a linear plane is ensured. The yarn, which moves in the linear plane, is sprayed with cold dyeing technique by means of the injectors in the dyeing group of the machine. In the last stage, the dyed yarn is transferred to the hank winding group.

Dyeing speed can be adjusted between 20-150 m/min from the control panel, depending on the yarn type, thickness and dyeing process.

For each group, there are paint preparation tanks with a capacity of 80 liters, independent of each other.

The hank winding group, which works synchronized with the machine, turns the dyed yarns into hanks. The yarns, which are skeined with umbrellas in the hank wrapping group, are simultaneously dried by means of infrared metallic heaters.

28 yarns can be skeined at the same time in the machine. It is also possible to take the dyed hanks from the spare hank winder while the machine is running.

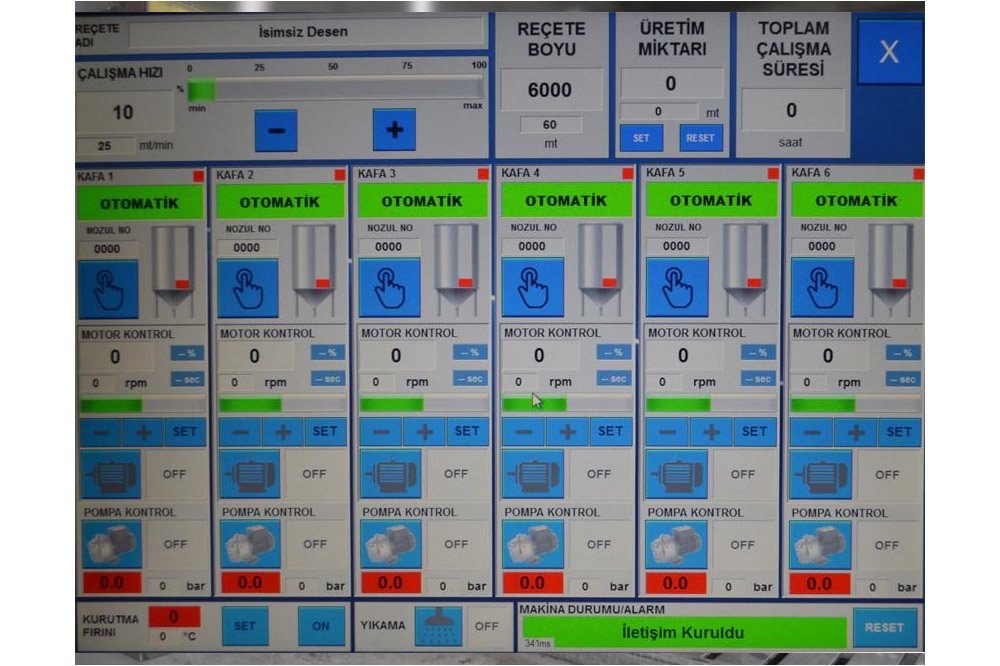

All kinds of operations on the machine can be performed via the PLC-based control panel. It is designed in such a way that the working speed of the machine and the amount of yarn printed in meters can be controlled and adjusted via the control panel. (15” Touch Panel TFT Industrial Panel PC)

Products of proven brands such as Schneider, Siemens and Omron are used in the control panel.

- Main Body Material: AISI316L

- Hank Hanger Length (mm): 1350 mm

- Control Panel: AISI304L

- Chemical Tank: 1 Set

- Dye Tank: 1 Set

- Max. Operating Temperature: 98°C

- Steam Working Pressure: 3 bar

- Heating Method: Buhar (direkt/endirekt)

- Solution Ratio: 1:7-8