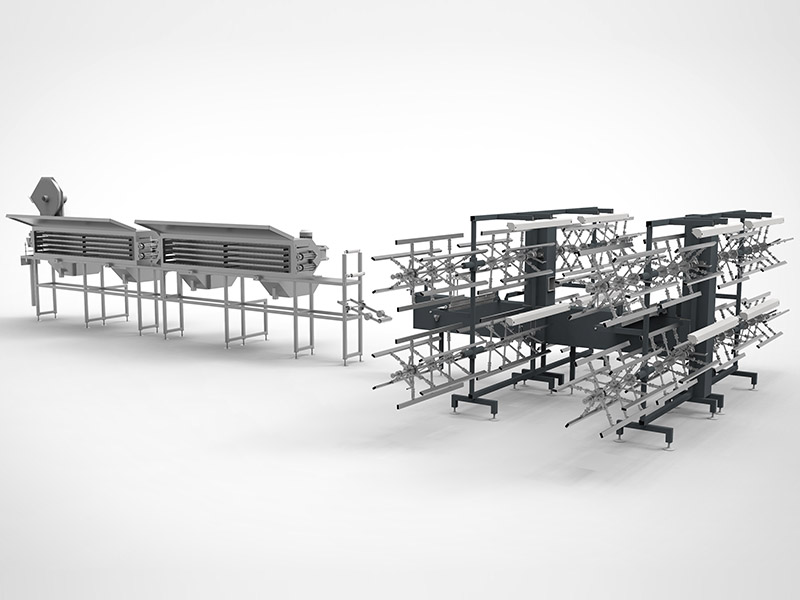

Smart Yarn Printing Machine

Yarn Printing Capacity : Machine designed to work 48 yarn threads at the same time. Maximum 50 meters/minute working speed. This speed is adjustable from control panel according to design and yarn type.

Printing System: Machine has cylindrical type mechanical printing system by felt. Printing operation occurs by pressing of felt covered cylinder. The dyestuff carried by cylinder to cylinder from dye tank. There is an adjustable apparatus cylinder to arrange dye stuff amount according to yarn type. Machine printing cylinders works synchronously smoothly and lower noise, this system also has time advantage during changing the design. Only one operator is enough to change the design cylinder.

Dye stuff preparation and transfer system: For each dyeing group the machine has 80 liters dye preparation tanks, transfer pump and by-pass system. Operator can prepare and add dye stuff while the machine works. The pump continuously transfers the dyestuff to dye basin and this circulation prevents from dyestuff precipitate.

Yarn Feeding Group: Machine inlet from bobbins. Bobbing feeding creel is designed for 48 threads and 48 threads as spare; total 94 bobbins.

Drying Unit: Drying unit is specially designed. It has 2 circulation fans, high efficient drying facility. All part has 5 cm thickness isolation. Heating by electric Cr-Ni material made resistances. Heat Sensor included. If machine stops, it has cold air by-pass system in drying unit to protect the yarns from go yellow.

Winding Unit: In this group the dyed yarn threads winded as hank from. This machine works synchronously by potentiometer with the dyeing unit. There is a tension adjustment unit included. There are 8 hank winder apparatus and also 8 apparatus as spare to supply non-stop working. Operator can take the dyed yarn hanks while machine is working.

Automation System: This control unit controls all operation process on machine. It is PLC based. The dyeing/design receipts are written on it. These receipts can be saving in memory. Machine working speed, the length of the printed thread can be adjusted and observed.